ethylene oxide sterilization cabinet is well-designed and crafted, mainly composed of microcomputer control system, residual gas treatment device, sterilization studio and other parts.

1.Ethylene oxide disinfection equipment is mainly used to achieve sterilization effect, because ethylene oxide has a very strong sterilization effect, and sterilization effect is very wide, such as a variety of microorganisms, bacterial spores. However, in the use of ethylene oxide disinfection equipment also need to pay attention to the safety issues. Ethylene oxide is a flammable and explosive gas.

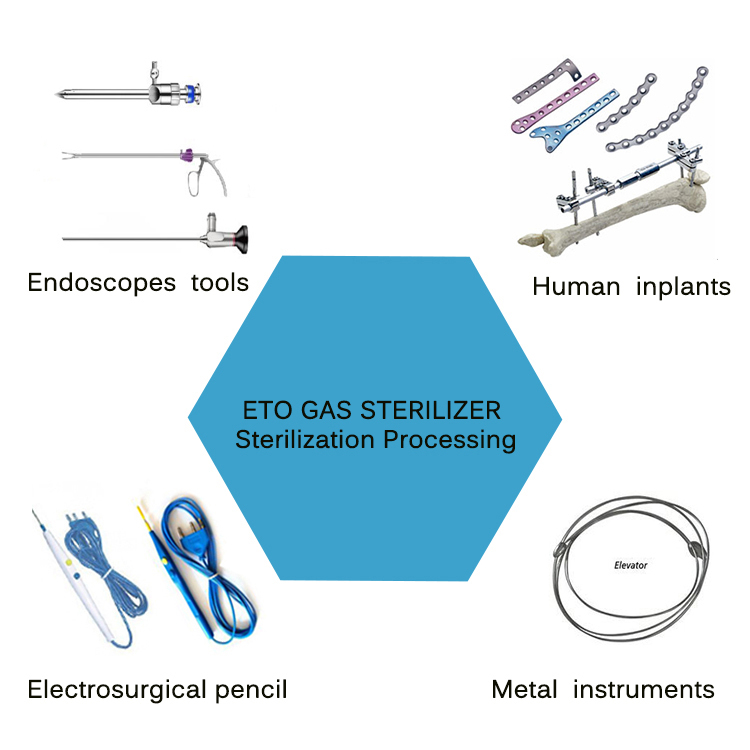

2.Ethylene oxide does not damage the sterilized items and has strong penetrating power, so most of the items that should not be sterilized by general methods can be disinfected and sterilized with ethylene oxide. For example, electronic instruments, optical instruments, medical devices, books, documents, furs, cotton, chemical fibers, plastic products, wood products, ceramics and metal products, endoscopes, dialyzers, and single-use medical supplies. Ethylene oxide is one of the very major low-temperature sterilization methods at present.

1.All technical indicators of the product are managed by computer automation, so the control is precise and reliable.

2.the advantages of the mixed ethylene oxide sterilization used are low toxicity, high efficiency and broad spectrum, complete sterilization, strong penetration, short sterilization time, no corrosion of the articles, no residue of the articles after sterilization, no pollution to the environment, so it is safe and reliable to use.

3.This series of products is the more advanced equipment in China's ethylene oxide sterilization instruments at present.